Winter Instruments Variometer (Vario)

Winter Instruments Variometer

Winter Instruments Variometer (Vario)

General Description

Winter Instruments Variometers (Vario) - Vane–type variometers measure the change in air pressure inherent to changes in altitude. The instrument consists of a cylindrical chamber with a precision–fit baffle plate (vane) rotating on shockproof jewel bearings and centered by a coil spring.

The vane divides the chamber in two: one section is open to static pressure, while the other is connected to an expansion tank, in which a volume of air is insulated against the thermal effects. Differences in pressure are compensated by the narrow gap between vane and chamber wall.

There is a change in static pressure when an aircraft climbs or descends, and a differential pressure is established between the two sections of the chamber. The resultant deflection of the vane provides a measure of the vertical speed and this deflection is transferred to the pointer of the instrument.

The response rate of a variometer is important. In high–performance gliding, up–currents can be identified all the quicker and used all the more efficiently if the variometer responds without delay. Defined as the length of time the instrument takes to reach 65% of its final reading in response to a sudden change in vertical speed, the time constant serves as a standard for gauging speed of response.

The faster a variometer responds, the smaller is its time constant. Vane-type variometers with large measuring ranges such as 5 StV 5 (10± m/sec. and ±15 m/sec.) have small time constants. The volume of the expansion tank must be increased in order to achieve comparable figures with variometers having the most common measuring range (±5 meters/second).

Wings & Wheels typically stocks the Varios highlighted in the table to the right. For other Varios please allow approximately 4 weeks Winter Instruments production time.

Technical Description

Purpose: Vane–type variometer for measurement of vertical speed of gliders, microlights and balloons

Principal mode of operation: The instrument works by measurement of the balancing flow which occurs with changes in air pressure between a balancing vessel and a static pressure of tapping point.

Scale types:

- 5 StV and 5 StVM: 270° – with linear graduations

- 5StVL and 5StVLM: 270° – with logarithmic graduations

Technical Data

Weight:

- 5 StV and 5 StVL: 0.25 kg.

- 5StVM and 5 StVLM: 0.24 kg

Indication error:

- at room temperature ± 10% over the whole range

- at –30°C to +50°C ± 15% over the whole range

Indication delay:

- 5 StV and 5 StVM: see table

- 5 StVL and 5 StVLM: When there is a sudden change in vertical speed from the upper limit of the scale to 0, the indication returns to 10% of the original value in 1 second.

Volume of the expansions tank:

- 5 StV and 5 StVM: see table ("Docs" Tab)

- 5 StVL and 5 StrVKM: 0.9 Liter

Application limits:

Max operating height: 12,000 m

Operating temperature rage:

–30°C to +50°C

Vibration resistance:

No resonances occur from translatory oscillation in the frequency range 5 to 50Hz. Zero point drift: 0.1 m/s max.

Magnetic effects:

No deflection of the compass needle at any distance between variometer and aircraft compass.

Overpressure resistance:

The variometer can't be continuously overloaded; abrupt pressure changes must be avoided.

Vario Models

StV Variometer – 80 mm

- • 80 mm (3 1/8″)

- ±m/s, ±ft/min, ±knots (depending on Item No.)

- 1.3, 1.6 or 3 second response time

- Requires the use of a Winter .45 L Capacity Flask

- Optional MacCready Ring

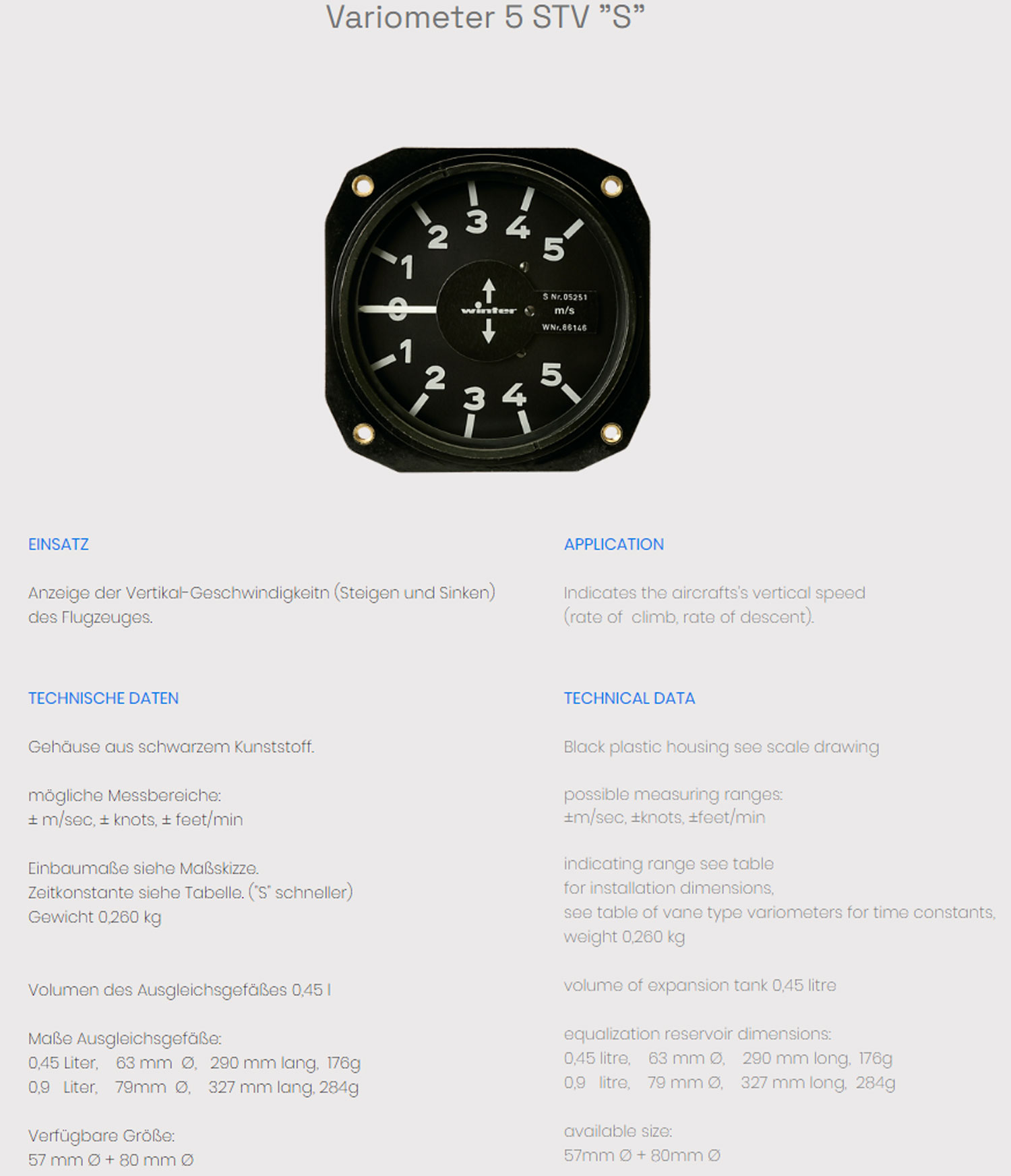

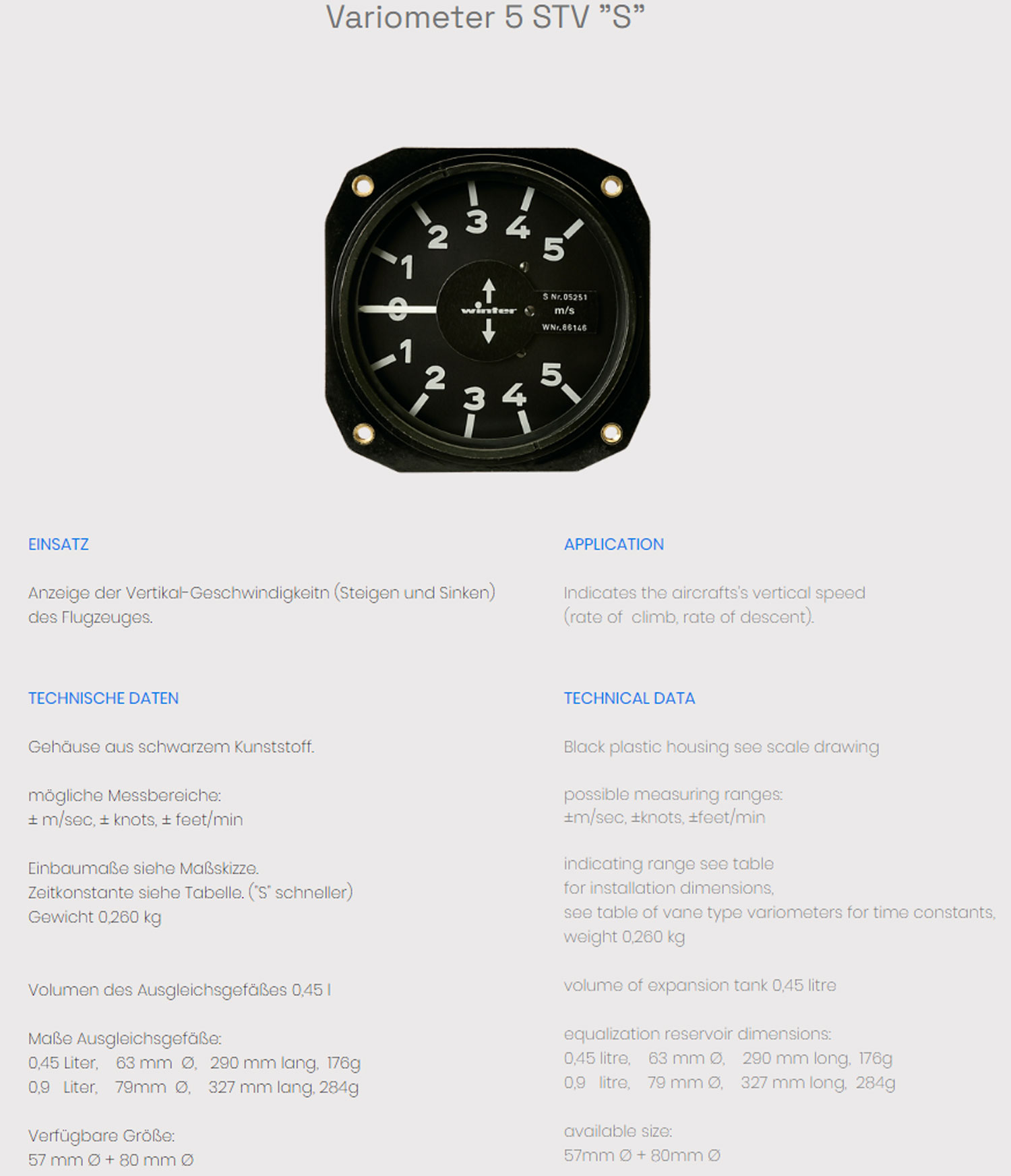

“S” (Sensitive) Model – 80mm

- 80 mm (3 1/8″)

- ±m/s, ±ft/min, ±knots (depending on Item No.)

- 1.8 second response time

- Requires the use of a Winter .90 L Capacity Flask or 2 x Winter .45 L Capacity Flask.

- Optional MacCready Ring

Indicates the aircraft's vertical speed (rate of climb, rate of descent). By using double the capacity used with the standard vario, this unit offers nearly twice as fast a response time. This variometer has a linear dial calibration so that it can be used with a MacCready Speed Ring.

StVM Variometer – 57 mm

- 57 mm (2¼″)

- ±m/s, ±ft/min, ±knots (depending on Item No.)

- 3 second response time

- Requires the use of a Winter .45 L Capacity Flask

- Optional MacCready Ring

“S” (Sensitive Model) – 57mm

- 57 mm (2¼″)

- ±m/s, ±ft/min, ±knots (depending on Item No.)

- 1.8 second response time

- Requires the use of a Winter .90 L Capacity Flask or 2 x Winter .45 L Flasks.

- Optional MacCready Ring

Indicates the aircraft's vertical speed (rate of climb, rate of descent). The variometer is the most valuable aid on all types of aircraft for pilots wishing to fully exploit the prevailing thermal conditions. This variometer has a linear dial calibration so that it can be used with a MacCready Speed Ring.

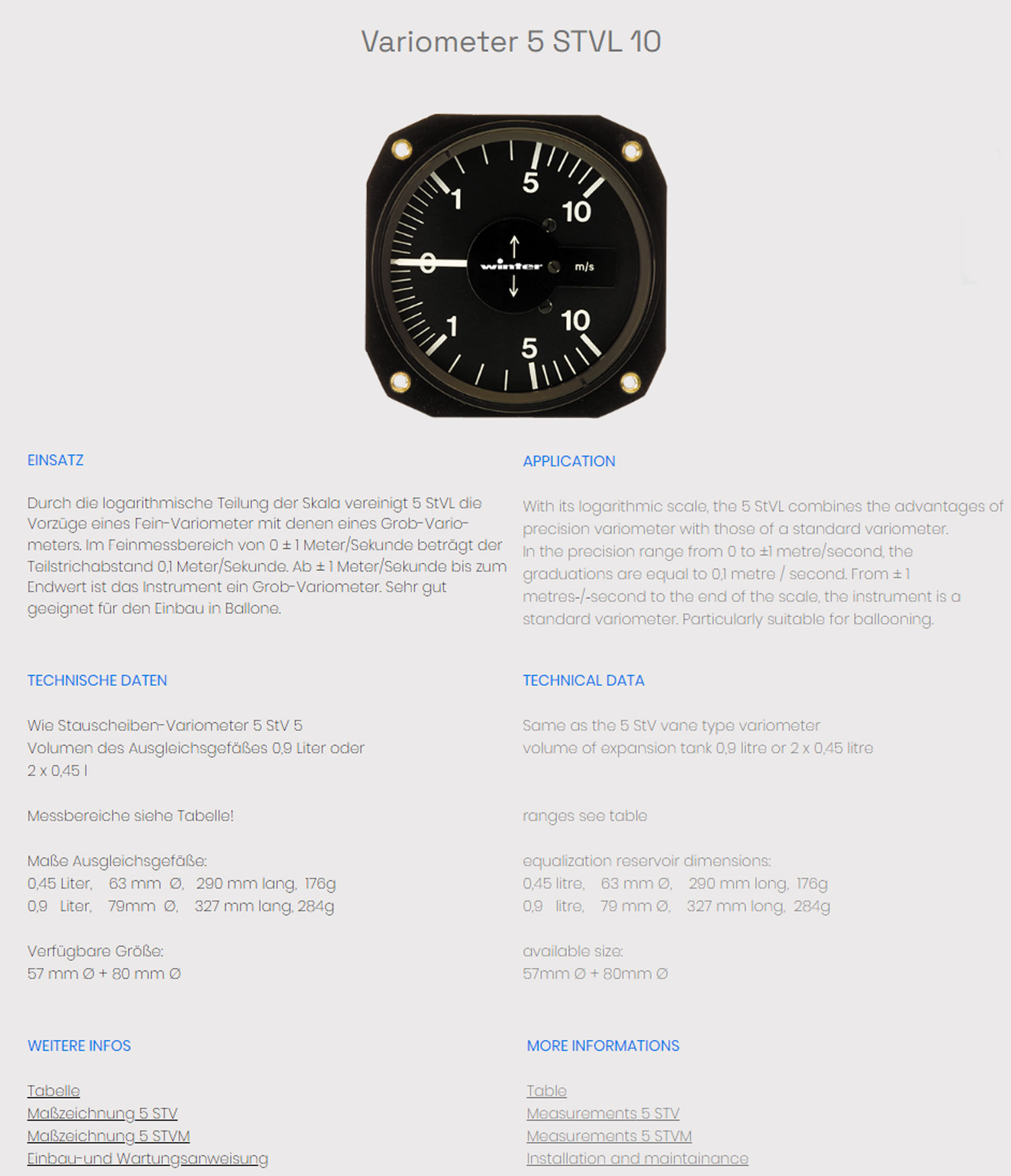

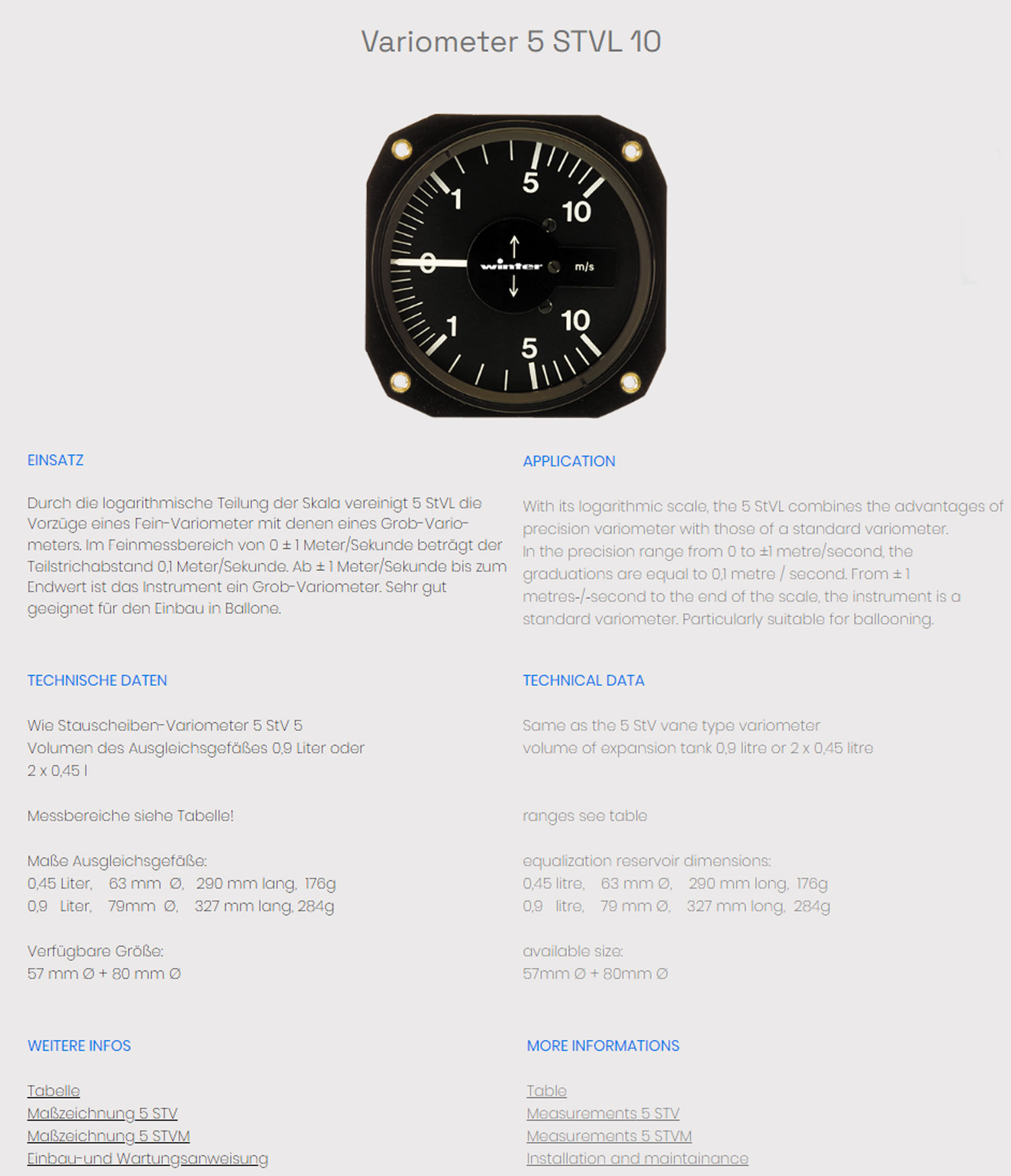

StVL Variometer – Logarithmic – Sensitive – 80 mm

- 80 mm (3 1/8″)

- ±m/s, ±ft/min, ±knots (depending on Item No.)

- Logarithmic Scale

- 1.6 second response time

- Requires the use of a Winter .90 L Capacity Flask or 2 x Winter .45 L Capacity Flasks.

With its logarithmic scale, the 5 StVL combines the advantages of precision variometer with those of a standard variometer. In the precision range from 0 to ±1 m/s, the graduations are equal to 0.1 m/s. From ± 1 m/s to the end of the scale, the instrument is a standard variometer. Particularly suitable for ballooning.

Note: Since the scale is not linear, this variometer cannot be used with a MacCready ring.

StVLM Variometer – Logarithmic – Sensitive – 57 mm

- 57 mm (2¼″)

- ±m/s, ±ft/min, ±knots (depending on Item No.)

- Logarithmic scale

- 1.6 second response time

- Requires the use of a Winter .90 L Capacity Flask or 2 x Winter .45 L Capacity Flasks

With its logarithmic scale, the 5 StVL combines the advantages of a precision variometer with those of a standard variometer. In the precision range from 0 to ±200 ft/min the graduations are equal to 20 ft/min. From ±200 ft/min to the end of the scale the instrument is a standard variometer. The needle travels farther in the low lift/sink range than in high lift/sink range – giving you more information when you need it in weak lift.

Note: Since the scale is not linear, this variometer cannot be used with a MacCready ring.

Winter Instruments Vario price varies depending on selection above.

| Item # | Model | Measuring Range | Diameter | Depth | Weight | Tank | Speed |

| 5161 | 5 VM | ± 10 m/sec | 80 mm ø | 68 mm | 0.450 kg | .45 L | 7.0 Sec |

| 5162 | 5 VM | ± 2000 ft/min | 80 mm ø | 68 mm | 0.450 kg | .45 L | 7.0 Sec |

| 5251 | 5 StV 5 | ± 5 m/sec | 80 mm ø | 68 mm | 0.450 kg | .45 L | 3.0 Sec |

| 5252 | 5 StV 5–2 | ± 1000 ft/min | 80 mm ø | 68 mm | 0.450 kg | .45 L | 3.0 Sec |

| 5253 | 5 StV 5–3 | ± 10 knots | 80 mm ø | 68 mm | 0.450 kg | .45 L | 3.0 Sec |

| 5261 | 5 StV 10 | ± 10 m/sec | 80 mm ø | 68 mm | 0.450 kg | .45 L | 1.6 Sec |

| 5262 | 5 StV 10–2 | ± 2000 ft/min | 80 mm ø | 68 mm | 0.450 kg | .45 L | 1.6 Sec |

| 5263 | 5 StV 10–3 | ± 20 knots | 80 mm ø | 68 mm | 0.450 kg | .45 L | 1.6 Sec |

| 5271 | 5 StV 15 | ± 15 m/sec | 80 mm ø | 68 mm | 0.450 kg | .45 L | 1.3 Sec |

| 5272 | 5 StV 15–2 | ± 3000 ft/min | 80 mm ø | 68 mm | 0.450 kg | .45 L | 1.3 Sec |

| 5273 | 5 StV 15–3 | ± 30 knots | 80 mm ø | 68 mm | 0.450 kg | .45 L | 1.3 Sec |

| 5281 | 5 StV 5 “S” | ± 5 m/sec | 80 mm ø | 68 mm | 0.560 kg | .90 L | 1.8 Sec |

| 5282 | 5 StV 5–2 “S” | ± 1000 ft/min | 80 mm ø | 68 mm | 0.560 kg | .90 L | 1.8 Sec |

| 5283 | 5 StV 5–3 “S” | ± 10 knots | 80 mm ø | 68 mm | 0.560 kg | .90 L | 1.8 Sec |

| 5351 | 5 StVL 5 | ± 5 m/sec, log | 80 mm ø | 68 mm | 0.560 kg | .90 L | 1.6 Sec |

| 5352 | 5 StVL 5–2 | ± 1000 ft/min, log | 80 mm ø | 68 mm | 0.560 kg | .90 L | 1.6 Sec |

| 5253 | 5 StVL 5–3 | ± 10 knots, log | 80 mm ø | 68 mm | 0.560 kg | .90 L | 1.6 Sec |

| 5361 | 5 StVL 10 | ± 10 m/sec, log | 80 mm ø | 68 mm | 0.560 kg | .90 L | 1.6 Sec |

| 5362 | 5 StVL 10–2 | ± 2000 ft/min, log | 80 mm ø | 68 mm | 0.560 kg | .90 L | 1.6 Sec |

| 5363 | 5 StVL 10–3 | ± 20 knots, log | 80 mm ø | 68 mm | 0.560 kg | .90 L | 1.6 Sec |

| 5431 | 5 StVM 2 | ± 2 m/sec | 57 mm ø | 62 mm | .0880 kg | 1.80 L | 2.2 Sec |

| 5451 | 5 StVM 5 | ± 5 m/sec | 57 mm ø | 62 mm | 0.340 kg | .45 L | 3.0 Sec |

| 5452 | 5 StVM 5–2 | ± 1000 ft/min | 57 mm ø | 62 mm | 0.340 kg | .45 L | 3.0 Sec |

| 5453 | 5 StVM 5–3 | ± 10 knots | 57 mm ø | 62 mm | 0.340 kg | .45 L | 3.0 Sec |

| 5461 | 5 StVM 10 | ± 10 m/sec | 57 mm ø | 62 mm | 0.340 kg | .45 L | 1.6 Sec |

| 5462 | 5 StVM 10–2 | ± 2000 ft/min | 57 mm ø | 62 mm | 0.340 kg | .45 L | 1.6 Sec |

| 5463 | 5 StVM 10–3 | ± 20 knots | 57 mm ø | 62 mm | 0.340 kg | .45 L | 1.6 Sec |

| 5471 | 5 StVM 15 | ± 15 m/sec | 57 mm ø | 62 mm | 0.340 kg | .45 L | 1.3 Sec |

| 5472 | 5 StVM 15–2 | ± 3000 ft/min | 57 mm ø | 62 mm | 0.340 kg | .45 L | 1.3 Sec |

| 5473 | 5 StVM 15–3 | ± 30 knots | 57 mm ø | 62 mm | 0.340 kg | .45 L | 1.3 Sec |

| 5481 | 5 StVM 5 “S” | ± 5 m/sec | 57 mm ø | 62 mm | 0.450 kg | .90 L | 1.8 Sec |

| 5482 | 5 StVM 5–2 “S” | ± 1000 ft/min | 57 mm ø | 62 mm | 0.450 kg | .90 L | 1.8 Sec |

| 5483 | 5 StVM 5–3 “S” | ± 10 knots | 57 mm ø | 62 mm | 0.450 kg | .90 L | 1.8 Sec |

| 5551 | 5 StVLM 5 | ± 5 m/sec, log | 57 mm ø | 62 mm | 0.450 kg | .90 L | 1.8 Sec |

| 5552 | 5 StVLM 5–2 | ± 1000 ft/min, log | 57 mm ø | 62 mm | 0.450 kg | .90 L | 1.6 Sec |

| 5553 | 5 StVLM 5–3 | ± 10 knots, log | 57 mm ø | 62 mm | 0.450 kg | .90 L | 1.6 Sec |

| 5561 | 5 StVLM 10 | ± 10 m/sec, log | 57 mm ø | 62 mm | 0.450 kg | .90 L | 1.6 Sec |

| 5562 | 5 StVLM 10–2 | ± 2000 ft/min, log | 57 mm ø | 62 mm | 0.450 kg | .90 L | 1.6 Sec |

| 5563 | 5 StVLM 10–3 | ± 20 knots, log | 57 mm ø | 62 mm | 0.450 kg | .90 L | 1.6 Sec |

Connection

The variometer must be connected to a static pressure and an expansion tank. The volume of the expansion tank must correspond to the volume for which the instrument was calibrated. Static pressure is tapped either from the second connection of the pilot tube or by static pressure sensors attached to the fuselage side. The pressure tapping point should be selected so that no errors are produced from air flow around the aircraft fuselage.

If fitted in a glider, it is recommended that the variometer is connected to a low pressure nozzle with a coefficient of –1, rather that to a static pressure (total energy compensation).

Hose leads should be as short as possible and must not be twisted or contain sharp bends. Kinking of hoses should be avoided in all cases. Hoses and connections must be absolutely leak–tight. The instrument must be protected from water penetration. If the hoses from the pressure tapping points cannot be run upwards, a water tap (water bag) should be fitted at the lowest point.

Testing for Leak–Tightness

Before putting into service, a test must be carried out for leak–tightness. If the aircraft manufacturer has not given any special instructions for this, our standard instruction for leak–tightness testing, January 1978 edition, can be used.

Maintenance Instructions

Leak testing should be carried out at least every 2 years. Otherwise, the instrument does not require any maintenance.

Accompanying Documents

New instrument:

- Test certificate EASA Form One, POE

- Installation and maintenance instructions.

Used Instrument:

- Test certificate EASA Form One, POE