TOST Weak Link

TOST Weak Links

General Description

TOST Weak Links - are required to protect the sailplane against overloading during launch operations. The strength of the spar of an aircraft is calculated on the basis of a given maximum load. The type and rating of the weak link used during the launch must meet the requirements of the sailplane as described in the Type Certificate Data Sheet (TCDS).

Weak links are fitted to aerotow ropes for the protection of both the sailplane and the tug. Weak link requirements may be found in some Aircraft Flight Manual (AFM) towing supplement, if available. For sailplanes, this information is found in the TCDS, the sailplane AFM, and the sailplane placards in the cockpit.

If the specified weak link strength for a heavy glider is greater than the specified strength for the tug, the operator is stuck with the weaker of the two values. Remember, sailplane weak link strengths are the maximum allowable to prevent structural overload of the sailplane; a lower strength weak link strength merely provides a higher safety margin. If the specified strength for a light glider is less than that specified for the tug, a separate weak link of the correct glider strength must be inserted at the glider end in addition to the one already in place at the tug end.

If only one weak link is fitted to an aerotow rope, it must be fitted at the tug end. This retains the protection in the event of the tug inadvertently snagging the rope on an obstacle on the final approach. Exception: a tug fitted with a TOST tow rope retraction system will have the weak link fitted at the sailplane end.

It is essential the tow pilot inspects the weak link and tow rope for serviceability before the day’s operation and also after being subjected to a high jolt or load. It is also required that when that weak link fails, the reserve link must also be replaced.

The TOST weak link system is an engineered and approved design that prevents aircraft overloading during winch, autotow and aerotow launching. By using this system, the operator is assured of maintaining the manufacturer’s airworthiness requirements assuring protection to both tow plane and sailplane.

TOST weak links are color coded and are available for loads from 80 to 1000daN with a tolerance of 10%. For conversion purposes, one decanewton is the equivalent of 1 kilogram force.

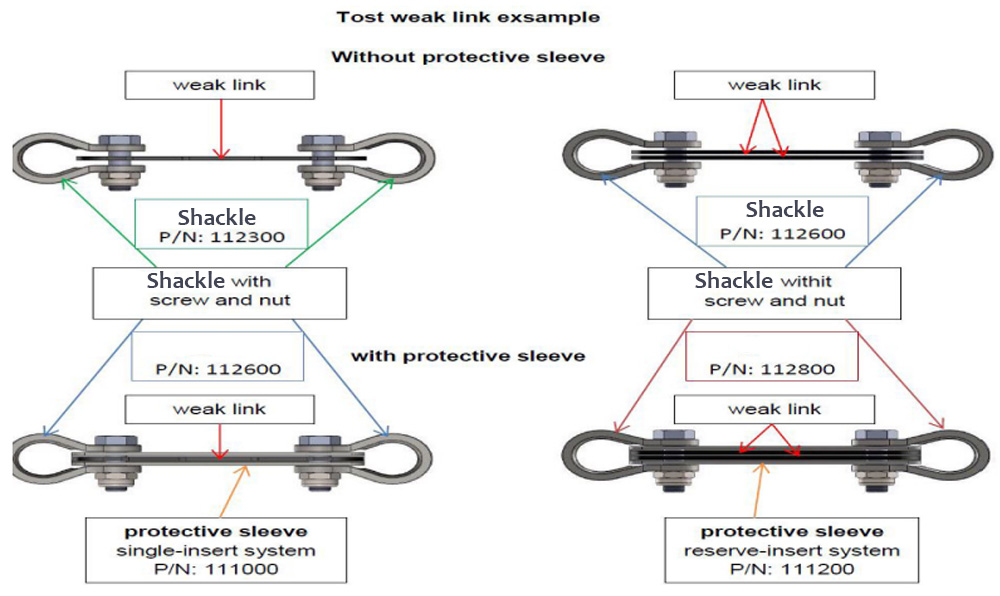

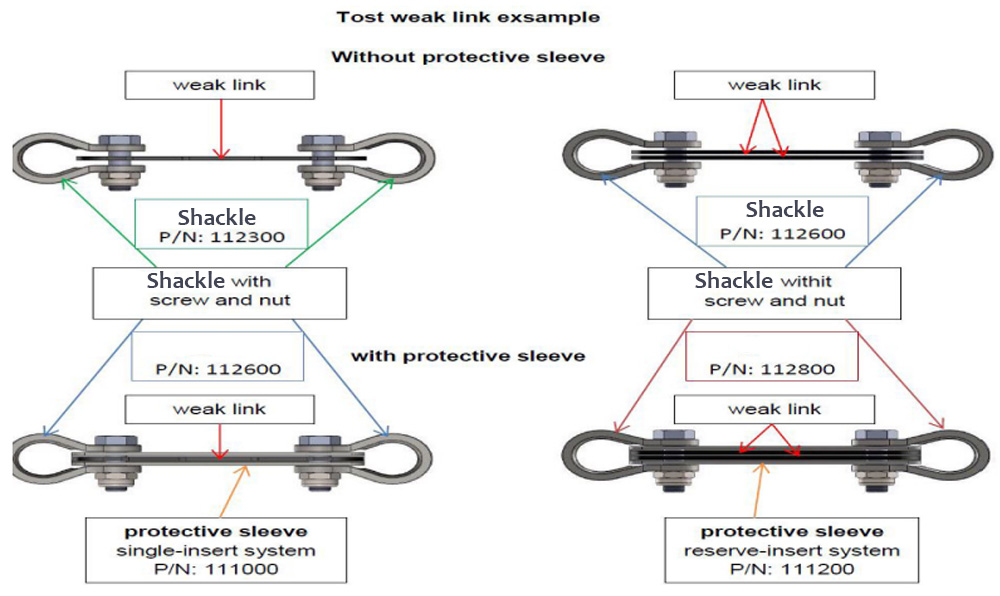

The GFA recommends clubs and operators use the TOST reserve insert and sleeved weak link system. This uses two weak links in parallel protected by a steel sleeve. Both weak links have attachment holes at each end and are 8 mm in length. The reserve has oval attachment holes and carries no load in normal operations. If the load exceeds the rating, the weak link will fail and the reserve link will take up the load. If the load is more than a momentary jolt both weak links will fail. Source: The Gliding Federation of Australia Inc.

Use above dropdown box for TOST Weak Link selection.

Load Table: Winch Launch and Aero Tow

|

Insert Number |

Color |

Breaking Load daN |

Single Insert (Round Hole) P/N / SKU |

Reserve Insert (Oval Hole) P/N / SKU |

| 1 | Black | 1000±100 |

110101 4992 |

110121 4989 |

| 2 | Brown | 850±85 |

110102 5010 |

110122 5007 |

| 3 | Red | 750±75 |

110103 5016 |

110123 5013 |

| 4 | Blue | 600±60 |

110104 5022 |

110124 5019 |

| 5 | White | 500±50 |

110105 5028 |

110125 5025 |

| 6 | Yellow | 400±40 |

110106 5034 |

110126 5031 |

| 7 | Green | 300±30 |

110107 5040 |

110127 5037 |

Load Table: Kites, Hang Gliders & Ultralights

|

Insert Number |

Color |

Breaking Load daN |

Single Insert (Round Hole) P/N / SKU |

Reserve Insert (Oval Hole) P/N / SKU |

| 8 | Mauve | 200±20 |

110108 5046 |

110128 5043 |

| 9 | Grey | 150±15 |

110109 5052 |

110129 5049 |

| 14 | Turquoise | 120±12 |

110114 5004 |

110134 5001 |

| 11 | Orange | 80±10 |

110111 4998 |

110131 4995 |

FAR Rules on Glider Towing

FAR 91.309 Towing: Gliders: (3) The towline used has breaking strength not less than 80 percent of the maximum certificated operating weight of the glider and not more than twice this operating weight. However, the towline used may have a breaking strength more than twice the maximum certificated operating weight of the glider if–

(i) A safety link is installed at the point of attachment of the towline to the glider or unpowered ultralight vehicle with a breaking strength not less than 80 percent of the maximum certificated operating weight of the glider and not greater than twice this operating weight;

(ii) A safety link is installed at the point of attachment of the towline to the towing aircraft with a breaking strength greater, but not more than 25 percent greater than that of the safety link at the towed glider end of the towline, and not greater than twice the maximum certificated operating weight of the glider.

Custom Weak Links

Using combinations of weak link inserts from different manufacturers can double the breaking load because of the elongation of inferior inserts. Refer to our Weak Link Application List for choosing the right weak link.

We manufacture to your requirements custom-made weak links with defined breaking load in the load range of 10 daN to 50 kN. Testing on computerized test equipment. Material: plastic, stainless steel, steel. Application examples: bracing of antennas, retaining of flagpoles, Off–Shore–operation, testing of parachutes, test racks, food industry.

Connecting Ring Pair

Connecting ring pairs are vital for the safe connection and reliable separation of tow cable and tow release.

The type certification stipulates that every Tost tow release must be operated only with a ring pair meeting the Aeronautical Standard LN 65091 (in its respective current edition).

These connecting ring pairs must be stamped with the manufacturer‘s name and the standard number.

Welded rings are categorically prohibited.

Their use voids the warranty of our releases. Welded rings cause damage to the releases. Moreover, undersized or deformed rings can cause the ring pair to jam the release and inhibit correct operation under load, a potential danger for the pilot.

Connecting ring pairs must be visually checked and measured at regular intervals.

Ring pairs that deviate from the standard dimensions must be replaced.

Wings & Wheels typically stocks all TOST Weak Links.

Always use TOST Tires and Tubes when available.

See "Tech Data" tab for Description, Application and Technical Data.

See "Docs" tab for "TOST Tire, Tube & Wheel Selection Guide".

Features

- Longer service life

- Correct marking with load group and manufacturer’s name

- Made of high-quality certified aircraft steel

- Clear distinction from inferior copies

- Manufacturing tolerance only 5% (in the requirements 10% are stipulated)

TOST weak links are manufactured according to EASA-approved production methods.

Each batch is tested on computerized test equipment and the results are documented. This guarantees consistently high quality and traceability.

Important Notes:

- Weak links protect your aircraft against overloading

- Use only the weak link stipulated in your aircraft TCDS or aircraft manual

- Checking the cable preamble is mandatory according to SBO (German Gliding Operation Regulations); this includes the inspection of weak links

- Replace the weak link immediately in the case of a visible damage

- We recommend that the weak link inserts are replaced after 200 starts; an insert exchanged in time is always safer and cheaper than one single aborted launch

- Always use the protective steel sleeve

- Use only the correct shackles; they prevent the weak link and the steel sleeve from twisting and hence an undefined increase of the breaking load

- Never use two equal inserts, e.g. both with round holes, in a reserve system since this would double the breaking load

Warning

Using combinations of weak link inserts from different manufacturers can double the breaking load because of the length change (elongation) of inferior inserts!