TOST G-Series Tow Release

TOST G-Series Tow Release

TOST G Series Tow Release

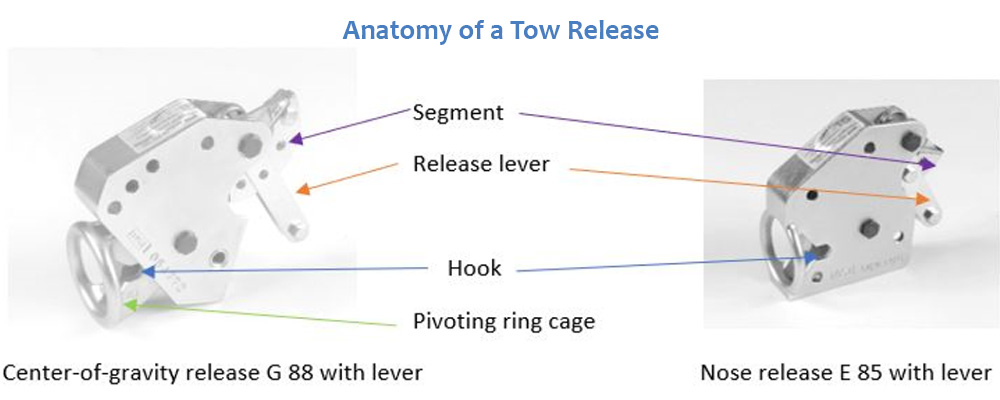

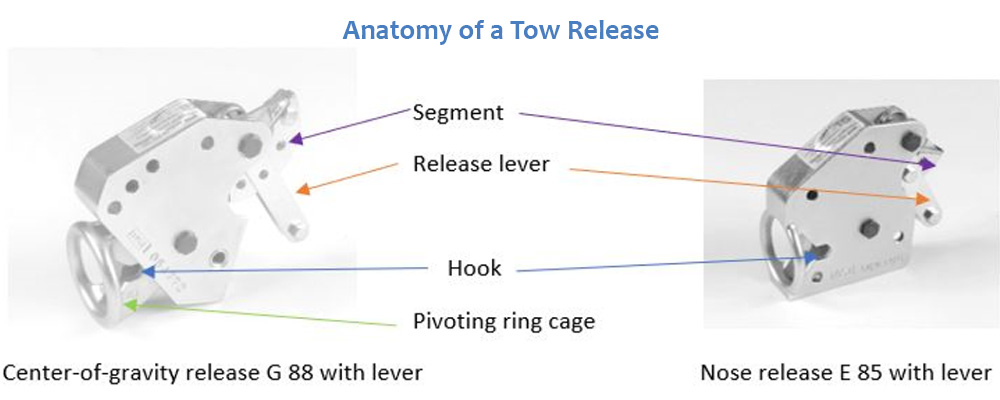

General Description

TOST G88 Series - The Europa G 88 safety release is installed at the center of gravity of gliders and motor gliders and are sometimes used for Aero-Tow release. These release types automatically back-release. The release is approved by the German Aviation Authority (LBA) under TCDS 60.230/2 to the airworthiness regulations for tow releases: for cable loads of up to 14.1 kN, for a maximum all-up weight of 900 kg, automatic release at a cable angle of 83°±7°, maximum manual release force is 140 N. The release also conforms to JAR 22 regulations.

Types are G-72, G-73 and G-88, all can interchange (from G-72, G-73 or G-88) and also from G-88 to G-73 or G-72. The differences are construction types (welded or machined parts, cases, segments etc.) and have no effect on strength of usage.

All Tow Releases NEW or O/H come with an EASA Form 1.

TOST G88 With Lever - Standard version, with 4-position release lever.

TOST G88 Without Lever - Allows for a special release lever to be fitted by the aircraft manufacturer. The release cable can also be attached directly to one of the segment holes.

TOST G88 1-83 Modification - For the cramped conditions in some gliders: the segment is shortened by three holes and the segment bolt is extended to fit a special release lever at the side of the release body.

TOST G–Series Tow Release price varies depending on selection. Use above dropdown box for selection and final price. Overhaul (OH) Releases are subject to stock on hand. Call to confirm availability.

G-88 (NEW) Tow Release

(Solid Body)

|

P/N SKU |

Desc | Weight g |

|

028000 4917 |

G 88 With Lever | 720 |

|

028000 4916 |

G-88 Short Lever For LS3 or LS4a |

|

|

028200 4918 |

G 88 No Lever | 670 |

|

028400 5146 |

G 88/1-83, Bushing 33x10x2, for Lever Left Hand | 670 |

|

028450 5144 |

G 88/1-83, Bushing 34.5x8x1, for Lever Left Hand | 670 |

|

028470 5139 |

G 88/1-83, Bushing 20x9x1,5, for Lever Left Hand | 670 |

|

028500 5143 |

G 88/1-83, Bushing 34.5x8x1, for Lever Right Hand | 670 |

G-88 (OH) Tow Release

(Subject to Availability)

| SKU | Desc | Remarks |

| 4950 | G-72 No Lever | Welded Body |

| 4955S | G-72 Short Lever | Welded Body |

| 4955 | G-72 Standard Lever | Welded Body |

| 4954 | G-72 PIK20 | Welded Body |

| 4957 | G-73 No Lever | Welded Body |

| 4956 | G-73 Short Lever | Welded Body |

| 4958 | G-73 Standard Lever | Welded Body |

| 4951 | G-73 1-83 | Welded Body |

| 4960 | G-88 No Lever | Solid Body |

| 4961S | G-88 Short Lever | Solid Body |

| 4961 | G-88 Standard Lever | Solid Body |

| 4963 | G-88 1-83 | Solid Body |

Installation

Do not change the glider manufacturer's original positioning of the release

Before removing the release, make a sketch, or take a photo, as a record for installing it again.

Tools needed: You need only some basic tools to install or remove the release in one piece. A No. 5 Allan key, a 10 mm closed-end wrench, or two 10 mm open–end wrenches.

To install a release use DIN 931–10. 9, or DIN 912–12.9 M6 bolts and DIN 985–M6–6 hexagon nuts.

Warning:

New bolts must have the same shaft length as the original ones. It is especially important that the thread is not subjected to load, and that the shaft does not protrude more than the thickness of a washer beyond the mounting, as the nut cannot then be tightened properly.

Torque: MA = 8.75 Nm (77.5 lb–in) The release must be installed so that it is not under stress. When a release has been removed, new nuts and bolts should be used when it is reinstalled.

After Installation

After installing a release, and as part of the periodic aircraft inspections, these checks must be carried out:

- You must be able to open the unloaded release completely by applying a force of 7.5 ± 1.5 daN (16.5 ± 3.3 lbs.) – measured on a spring balance – on the manual release lever in the cockpit over the full travel of the release actuation arm.

- When the release hook is under a load of approx. 150 daN (330 lbs.), you should still be able to operate the manual release lever in the cockpit with the same force, i.e., 7.5 ± 1.5 daN (16.5 ± 3.3 lbs.).

- If both a nose and a center–of–gravity release are connected to the same release cable, the manual force required to operate them from the cockpit may not exceed 17 daN (37 lbs.), even if one of the releases is under a load of 150 daN (330 lbs.).

Care and Cleaning

The release is largely protected against corrosion. But certain components like the hook cannot get surface protection due to strength reasons. Therefore regular cleaning and servicing is imperative for maintaining the required security level.

Regular Check

During operation and especially when landing away from paved runways, your release is exposed to dirt and pollution. So it is important to check the release before and at the end of every flight operation and to clean it if necessary. This point is indispensable especially if not used daily.

Valid from July 2001

TBO (Time Between Overhauls) 2000 launches accordingly 10.000 actuations

Life limiting part is the release spring, with a life expectancy of about 10.000 actuations. With about 5 actuations in normal flight operation - like in Germany - this is, as before, 2000 launches.

Should you have more actuations per launch in pure training operation the TBO is reduced accordingly (e. g. with 8 actuations per launch the TBO would be 1250 launches).

If you have only 2 actuations per launch, the TBO consequentially would be 5000 launches.

This decision – after how many launches the 10.000 actuations are accomplished – is in the responsibility of the aircraft holder.

If both releases are actuated together (like in Germany) both releases have to be sent for overhaul after having performed the adequate number of launches.

The life limit of 4 years is replaced by a manufacturer's recommendation.

The new regulation had been published from the LBA in the "NfL" on July 12, 2001 and therefore is valid right now.

Please note that the new regulation can be applied only to releases which had a valid certificate in 2001!

Since 1952 Tost company has manufactured releases for gliders. The first product was the manual actuated nose release type “BUG”.

1953 followed the first Tost safety release (Universal), that has been installed near to the center-of-gravity. Its automatic release at a defined cable angle made the winch launch safe.

Tost releases are the standard worldwide for safe gliding starts for all types of starts and are being operated “from Australia to Cyprus”.

In total, more than 73.000 units have been produced. All are still being serviced, also those units from the very beginning. Most of the releases are still serviceable and even in service for further decades.

History of Tost releases

During the decades, Tost releases have been developed further and optimized as well. The sequence of the release types is as follows:

For the nose and tail releases: BUG - E 72 - E 75 - E 85

For the center-of-gravity releases: UNIVERSAL - KK - G 72 - G 73 - G 88

One important step to high dimensional accuracy and rigidity of the releases was the use of precision casting components: hook, segment, ring automatic as well as fi ne cast release housing as successor of the welded release housing (up to type

E 72 and G 72). When used in vintage gliders, please always check the installation space: narrow release brackets possibly may not allow the installation of the latest release types G 73/G 88 and E 75/E 85, which need a bit more space.

A further milestone was the increase of the cable force from 11,7 kN for the predecessor types to 14,1 kN for the E 85 and G 88 series.

The exchange of the elder release types against the recent ones has always been guaranteed through the retention of the outer dimensions and fixation holes of the releases.

Important operating advise to the connecting ring pair

Connecting ring pairs are vital for the safe connection and reliable separation of tow cable and tow release.

The type certifi cation stipulates that every Tost tow release must be operated only with a ring pair meeting the Aeronautical Standard LN 65091.

Such a ring pair must be stamped with the manufacturer's name and the standard number. Welded ring pairs are generally prohibited and imply a potential danger for the pilot. Their use voids our warranty for the release. Welded rings damage the release. Moreover, undersized or deformed rings can cause the ring pair to jam the release and inhibit correct operation under load.

Ring pairs must be visually checked and measured at regular intervals to ensure correct operation. Ring pairs that deviate from the standard dimensions must be replaced.

Overhaul (OH) releases are subject to availability. Most tow releases are in stock. Some may require special order.

Wings & Wheels normally stocks the Tow Releases highlighted in yellow in the Tech Data" table. All other P/Ns are special order items. Please allow approximately 4 weeks delivery for special order items.

Please Note: The number stamped on your release is the Serial Number - Not the Part Number. There are no identifying numbers on the release itself that will help identify the type.

Need help identifying your release type? We're happy to help! email us a few pictures of your Tow Release (removed from the aircraft) to [email protected]

Core Return

Unlike a car battery - TOST Tow Releases do not have a Core Deposit at the time of sale. However, send us your used Tow Release for a US$80 refund (most releases, depending on condition).

Return for Overhaul

Return for Overhaul - you may also return your release to W&W and have that exact release overhauled by TOST. The price for overhaul is the same as an overhauled price of that model in the dropdown.

W&W returns releases for overhaul several times a year in large batches. Your release will be included in the next large batch return. Lead time can be 2-3 months.